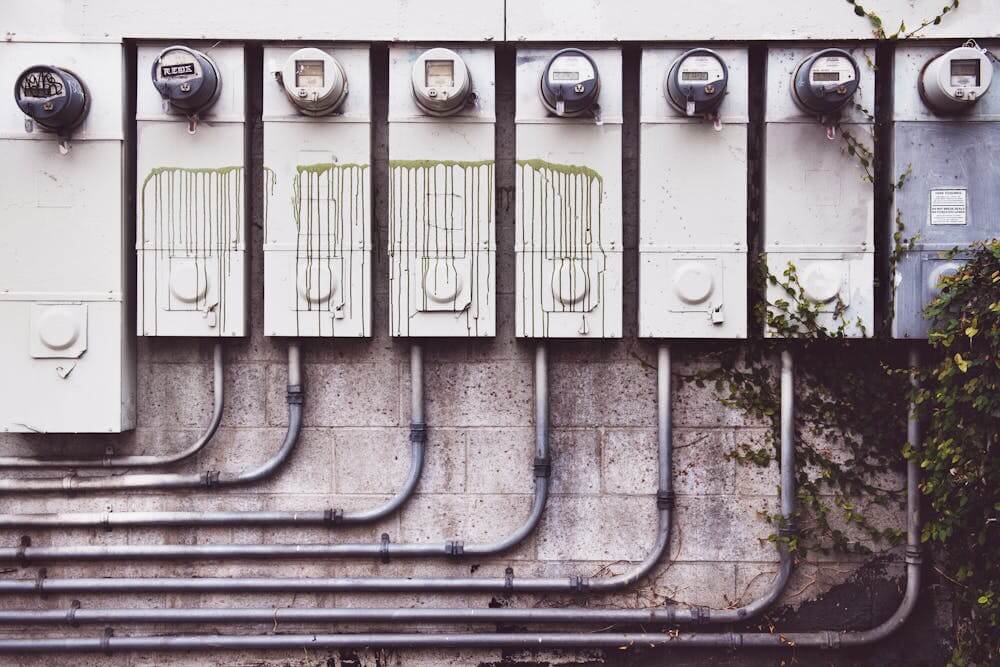

Growth is exhilarating. New markets, bigger teams, and higher output all signal success. But behind the scenes, your power infrastructure is under strain. Ignore it, and you risk outages and equipment damage, as well as spiralling costs. Get it right, however, and you’ll scale with confidence.

Power Infrastructure Matters

Every additional workstation or server adds to your electrical load. If your system wasn’t designed for this, you’ll face overloaded circuits or unstable voltage – on top of compliance headaches. They can halt production and compromise safety.

Think of power infrastructure as the backbone of your operations. When it fails, everything else grinds to a halt. A single hour of downtime can cost thousands in lost productivity. For businesses in manufacturing or data-heavy sectors, the stakes are even higher.

And as always, planning ahead is cheaper than firefighting. A structured approach ensures your infrastructure grows with your business, not against it. That means anticipating future demand, not just reacting to today’s needs.

Core Components to Monitor

Start with the fundamentals. Three areas deserve your attention:

- Load Capacity: Understand your current demand and forecast future needs; overloading is both inefficient and dangerous. Excessive load can cause overheating, tripped breakers, and even fires. Use historical data and growth projections to model future consumption accurately.

- Redundancy: Backup systems aren’t optional. They keep operations running when the unexpected happens – whether that’s a grid failure or an internal fault. And they will Consider uninterruptible power supplies (UPS) for critical equipment and generators for extended outages.

- Quality of Supply: Voltage stability and frequency consistency protect sensitive equipment. Fluctuations can damage electronics, corrupt data, and shorten the lifespan of machinery, but power quality analysers can detect irregularities before they escalate.

Regular audits are essential. A qualified electrical engineer can identify weaknesses invisible to the untrained eye. These checks should cover wiring integrity, breaker capacity, and compliance with UK regulations such as BS 7671.

Tools and techniques for precision

Modern monitoring tools make infrastructure management smarter and more proactive. Smart meters provide real-time consumption data, helping you spot inefficiencies and peak loads. Power quality analysers go further, highlighting fluctuations that could harm equipment.

For complex systems, such as those in manufacturing plants or data centres, advanced diagnostics are indispensable. Instruments like spectrum analyzers, typically used in signal integrity testing, can reveal interference patterns and anomalies in electrical signals. While they’re more common in telecoms and electronics, their role in diagnosing intricate power issues is growing.

Why does this matter? Because precision prevents waste. Data-driven decisions allow you to upgrade only what’s necessary, avoiding costly over-engineering. They also help you schedule maintenance intelligently, reducing downtime and extending asset life.

Building a Scalable Strategy

Scaling is also about building flexibility. Here’s how to do it:

- Forecast demand: Use growth projections to estimate future load. Factor in seasonal peaks, new equipment, and potential expansions.

- Invest in modular systems: Modular switchgear and distribution boards allow incremental upgrades without major disruption. This approach saves time and reduces capital expenditure.

- Prioritise preventive maintenance: Reactive fixes are expensive and disruptive. Preventive maintenance – regular inspections, thermal imaging, and load testing – keeps systems healthy and predictable.

- Collaborate with certified professionals: Electrical engineers ensure compliance with UK standards and help integrate energy-efficient solutions. Their expertise can prevent costly mistakes.

- Think sustainability: Energy-efficient equipment reduces operating costs and supports ESG goals. Consider LED lighting, variable-speed drives, and power factor correction to optimise consumption.

Compliance and Risk Management

UK businesses must comply with the Electricity at Work Regulations 1989 and the aforementioned BS 7671 wiring standards. Non-compliance can lead to fines, legal liability, and insurance complications.

Document everything. Maintenance logs, inspection reports, and upgrade plans demonstrate due diligence. They also make audits smoother and protect your business in the event of an incident.

It’s tempting to postpone infrastructure upgrades when budgets are tight. But the cost of neglect is far higher. Downtime can cripple operations. Equipment damage leads to expensive repairs or replacements. Worst of all, safety risks can result in injury or litigation. Instead, invest in monitoring, maintenance, and modularity today, and you’ll build a foundation strong enough to support tomorrow’s ambitions.